Today, I would like to give you an insight into one of the major debates in the manufacturing process. If you have ever worked with production planning in Business Central, you have probably come across two common tools – MRP (Material Requirements Planning) and MPS (Master Production Scheduling).

At first glance, they might seem like twins. But once you start using them, you will realize they serve two different purposes that complement each other beautifully.

Let us break it down in simple way.

Table of Contents

What is MRP (Material Requirements Planning)?

Think of MRP as your materials planner. It makes sure you have all the parts, components, and raw materials needed to make your products – exactly when you need them.

MRP looks at:

- What is already in your inventory

- What is on open sales and production orders

- How long suppliers take to deliver (lead times)

Then it tells you what to buy, when to buy it, and in what quantity – so you do not run short or overstock.

For Example:

If you manufacture bicycles, MRP checks whether you have enough tires, chains, and seats. If not, it plans purchase orders so the parts arrive just before production starts.

What is MPS (Master Production Scheduling)?

MPS works one step higher – it is your production planner.

Instead of focusing on materials, MPS looks at finished goods – the actual products you sell to customers.

It helps answer:

- What should we build?

- How many should we build?

- When should we build them?

Example:

If you expect to sell 1,000 bicycles next month, MPS creates a production plan to make sure those 1,000 bikes are built on time.

Key Difference Between MRP and MPS

Following table shows the key difference between MRP and MPS.

| Feature | MRP (Material Requirements Planning) | MPS (Master Production Scheduling) |

|---|---|---|

| Focus | Components, raw materials | Finished goods or top-level items |

| Purpose | Ensures you have enough materials | Ensures production meets customer demand |

| Input | Inventory, open orders, BOMs | Sales forecasts or firm orders |

| Output | Purchase and production suggestions | Production schedule for finished goods |

| Used by | Inventory and procurement planners | Production planners and schedulers |

How MRP and MPS Work Together

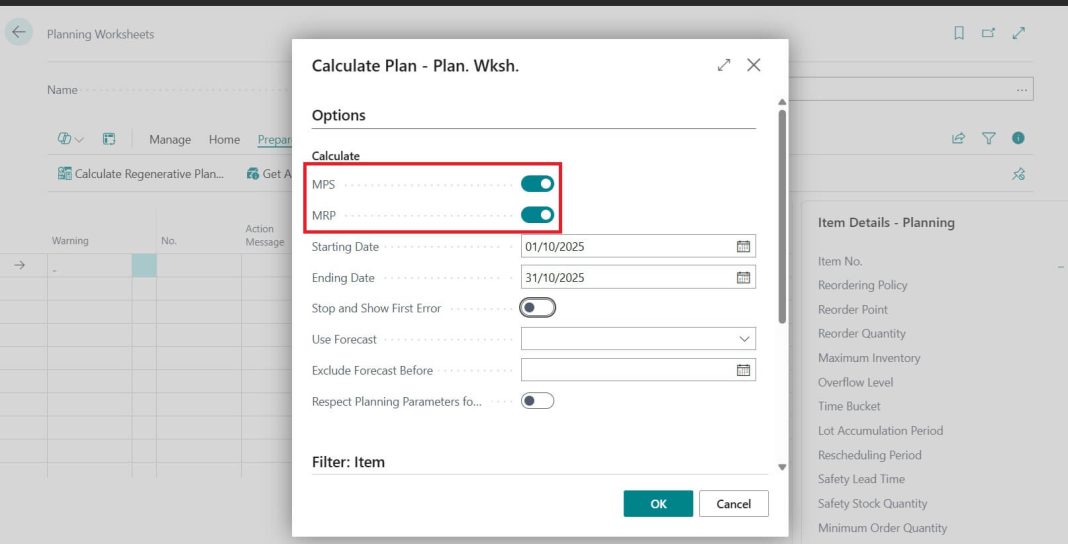

In Business Central, MPS runs first, then MRP follows.

- MPS creates a plan for finished goods.

- MRP checks what materials are needed to make that plan happen.

Together, they ensure you have both the right products ready for sale and the right materials ready for production.

Why It Matters for Your Business

- No more last-minute surprises : You will know what is needed well in advance.

- Lower inventory costs : You buy and make only what is required.

- Happier customers : Orders are fulfilled on time.

- Better teamwork : Production, procurement, and sales teams all stay aligned.

In simple words:

- MPS decides what to make and when to make it.

- MRP ensures you have the materials to make it happen.

Used together, they make Business Central a powerful planning engine – one that keeps your shop floor moving and your customers smiling.

FAQ : MRP vs MPS in Business Central

Following are the FAQs for the difference between MRP and MPS in Business Central

MRP (Material Requirements Planning) helps you plan and purchase the materials and components needed for production. It ensures you have the right stock at the right time.

MPS (Master Production Scheduling) focuses on finished goods. It helps plan what to produce, when to produce, and how much to produce based on sales demand or forecasts.

MPS creates the plan for finished goods, and MRP ensures all the required materials are available to support that plan. Together, they balance supply and demand efficiently.

Use MPS when planning top level or final products.

Use MRP when managing parts, raw materials, and subassemblies.