If you have ever worked in a warehouse, you know the pain of doing a full physical stock count. Shutting everything down, counting every single item, and then realizing you missed something it’s exhausting. That’s exactly why Cycle Counting in Business Central exists.

Instead of waiting until year-end or month-end to do one massive count, you can count small batches of items more frequently. Think of it like checking your wallet daily instead of waiting until the end of the month to figure out where your money went. Much easier, right?

In Business Central, Cycle Counting is built into the Warehouse module to help you:

- Keep inventory accurate without stopping operations.

- Spread counting tasks across days or weeks.

- Catch mistakes early before they pile up.

I have seen many warehouses move from a stressful “all day stock take” to a smooth cycle counting routine and trust me, it is a game changer.

Table of Contents

How Cycle Counting Works in BC Warehouse

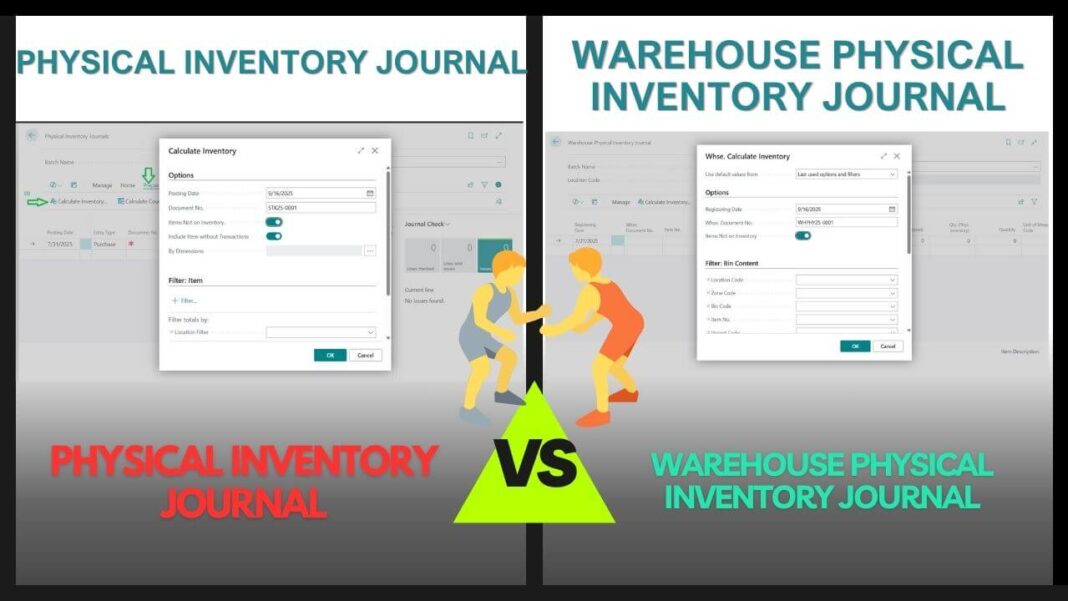

In Business Central, cycle counting is done using the Warehouse Physical Inventory Journal.

Following are the simple process for the same.

1. Select Items to Count

You do not need to count everything at once or else You may choose which items (or bins) to check today.

2. Create a Cycle Count in Business Central

Use the Warehouse Physical Inventory Journal to list the items scheduled for counting.

Click on Calculate Inventory to open the window like following image. Where you will get option for filtering the record for cycle counting.

3. Do the Actual Count

Your warehouse staff checks the items physically and enters the quantities in BC. Enter the Quantity in the Qty. (Phys. Inventory) column. Once you entered this value you may notice the difference quantity reflected automatically. That means it will work almost same process like Physical Inventory Journal detailed process explained last day.

4. Post Adjustments

Business Central compares the actual count with system records. If there’s a difference, it posts an adjustment to align the system with reality.

Example

Imagine you have a warehouse with 500 items. Instead of counting all 500 in one day, you set up a cycle count plan:

- Count 50 items every week.

- In 10 weeks, all items will be checked at least once.

This way, your stock data stays fresh, and the work is spread out.

Pro Tips for Cycle Counting in Business Central

Following the key tips to be consider for Cycle Counting

- Prioritize fast moving items (count them more often).

- Schedule cycle counts so your team knows when to do them.

- Always use Warehouse Physical Inventory Journal if you have advanced warehouse setups with bins.

- For simpler setups, you can use the Physical Inventory Journal instead.

Pro Tip: Start small. Do not try to cycle count hundreds of items in a day. Pick your fast-moving or high value items first and build the habit gradually.

FAQ – Warehouse Cycle Counting Process in Business Central

Following are some of the FAQs for this topic for reference

Cycle counting is the process of counting small batches of items regularly instead of doing a full physical stock take. It helps keep warehouse stock accurate without stopping daily operations.

Use the Warehouse Physical Inventory Journal if your company uses advanced warehouse setups with bins or zones. For simple setups, the regular Physical Inventory Journal is enough.

Cycle counting saves time, reduces errors, keeps stock accurate, and avoids business disruptions. It also improves planning, purchasing, and sales decisions.

It depends on your business. Fast-moving items can be counted more often (daily or weekly), while slow-moving items can be counted monthly or quarterly.

Please share your valuable feedback also advised you to share the topic where you want details. Also can share error you are facing to get resolution and more details on the same.